Standard Operating Procedure (SOP) for Operation, Cleaning and Qualification of Biosafety Cabinet (ESCO) used to storage of Microbiological Media, Cultures and other material used in laboratory.

Biosafety Cabinet (ESCO)

1.0 PURPOSE:

-

- To lay down the procedure for operation, cleaning and qualification of Biosafety Cabinet (ESCO).

2.0 SCOPE:

-

- This Standard Operating Procedure is applicable at Microbiology Department for Handling of Biosafety Cabinet (ESCO).

3.0 REFERENCES:

-

- User manual of Biosafety Cabinet (ESCO).

4.0 RESPONSIBILITY:

-

- Officer or Executive of Microbiology department shall be responsible for preparation of new or revision of existing SOPs.

-

- Head of the department / designee of respective areas & QA shall be responsible for reviewing the SOPs.

-

- QA shall be responsible for distribution and control of SOPs to various departments.

5.0 ABBREVIATIONS:

-

- BSC : Biological safety cabinet (Biosafety Cabinet -ESCO)

-

- CC : Change Control

-

- Fpm : Feet Per Minute

-

- IPA : Isopropyl alcohol

-

- LCD : Liquid Crystal Display

-

- m/s : Meter per second

-

- UV : Ultra violet.

6.0 PROCEDURE FOR HANDLING OF BIOSAFETY CABINET (ESCO) :

-

-

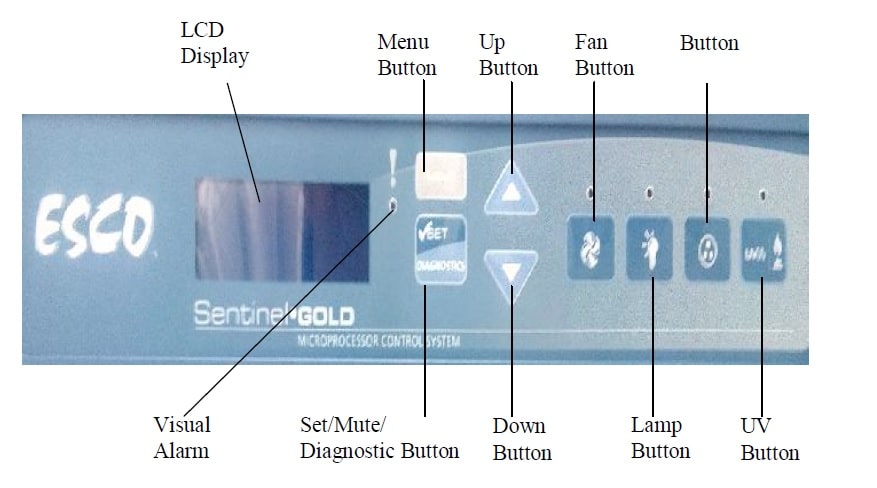

Sentinel Control System of Biosafety Cabinet (ESCO) :

-

-

- Fan Button

-

- Turn on and turn off the fan.

-

- Select between full speed and half speed.

-

- Lamp Button

-

- Turn on and turn off the fluorescent lamp.

-

- UV/Gas Button

-

- Turn on and turn off the UV Lump.

-

- UV lamp can only be activated when the sash window is fully closed.

-

- Since the sash is capable of filtering UV rays, users are protected from the harmful UV radiation.

-

- Turn on and turn off Gas (if required)

-

- Up (▲) and Down (▼) Arrow button

-

- Move the menu option upwards and downwards.

-

- Increases and decreases corresponding value inside one of the menu options.

-

- For accessing the stopwatch and experiment timer function

-

-

Set or Mute or Diagnostic Button

-

-

- To proceed to the next step, level or sequence inside the menu options.

-

- Mutes the fully opened sash and air fail alarm sound (During normal and quick start mode).

-

- Enters diagnostic mode.

-

- Menu button

-

- To enter and exit from the menu options.

-

- Go back to the previous level of the menu options.

-

- To access maintenance mode from error condition.

-

-

Setting of Biosafety Cabinet (ESCO) :

-

-

- Set Clock (Time):

-

- Set the time by increasing/decreasing the hour and minutes values.

-

- The correct time will be maintained even after the unit is turned off.

MENU ⇒ SETTING ⇒ SET TIME ⇒ HH:MM

-

- UV Timer:

-

- UV timer can be used to switch off the UV lamp automatically after a fixed period.

-

- The UV timer is activated, the lamp has to be switched off manually.

MENU ⇒ SETTING ⇒ UV TIMER ⇒ HH:MM

-

- Experiment Timer:

-

- Timer is a countdown timer that can be used for critical experiment.

-

- Experiment timer can be set between “00:00:00” and “17:59:59”.

MENU ⇒ SETTING ⇒ EXPERIMENT TIMER ⇒ HH:MM:SS

-

- Measurement Unit:

-

- Using this option, the user can select the unit in witch air velocity is measured and displayed.

-

- The user can choose between metric (m/s) and imperial (fpm) units.

MENU ⇒ SETTING ⇒ MEASUREMENT ⇒ METRIC/IMERIAL

-

-

Warm up time:

-

-

- There will be a warm up period before the Biosafety Cabinet (ESCO) is fully functioning upon activation of the unit.

-

- This is to ensure that the sensors, the blower and the control system are stabilized as well as to ensure the work zone is purged of contaminations.

-

- The default setting is 3 minutes and it can set between 3 to 15 minutes as per requirement.

MENU ⇒ SETTING ⇒ WARM UP TIME ⇒ XX MINUTES

-

-

Post Purge Time:

-

-

- After the user switches off the Biosafety Cabinet (ESCO) blower.

-

- There will be a post-purge period to ensure that all contaminants are purged from the work zone.

-

- The default setting is zero minute (disabled) and it can set from 0 up to 15 minutes.

-

- The Biosafety Cabinet (ESCO) is purged for a minimum of 3 minutes after the work is complete.

MENU ⇒ SETTING ⇒ PURGE TIME ⇒ XX MINUTES

-

- Set Date:

-

- Set the date by increasing/decreasing the year, month and day values.

-

- The correct date will be maintained even after the unit is turned off.

MENU ⇒ SETTING ⇒ SET DATE ⇒ YYYY-MM-DD

-

- Setting Mode:

-

- The Biosafety Cabinet (ESCO) has three modes and two of witch, normal mode and quick start mode, can be used in daily activity.

-

- Both of these modes can be seen and accessed when you enter the FAN PIN.

-

- The last mode, maintenance mode is for the use of qualified personnel during maintenance.

MENU ⇒ SET MODE ⇒ METRIC/IMERIAL

-

- Normal Mode:

-

- The normal mode is activated by factory default. In this mode all alarm and interlock are enabled.

-

-

Quick start Mode:

-

-

- Quick start mode allows the user to activate the blower by simply lifting the sash from fully closed position and the light by simply lifting the sash window to the operating position.

-

- In this mode all alarm and interlocks are enabled.

-

- Maintenance Mode:

-

- Maintenance mode should only be accessed by qualified personnel during maintenance.

-

- In this mode all alarms are disabled and all interlocks are defeated.

-

Operation of Biosafety Cabinet (ESCO):

-

- Turn on the main switch.

-

- Open the sash and Wipe work tray and interior walls with 70% IPA or other appropriate validated disinfectant.

-

- Closed the sash and turn on UV.

-

- After UV burning (30 Minutes) lift the sash up to the Sash height.

-

- Turn on the fan.

-

- Press SET to mute alarm.

-

- Wait for 3 minutes for worm up.

-

- Checks the velocity (inflow velocity 0.45±0.02 m/s & downflow velocity 0.30±0.02 m/s) in display and record in annexure-1.

-

- Before start work the inflow and downflow velocity shall be within limit.

-

- After completion of work Wipe work tray and interior walls with 70% IPA or other appropriate validated disinfectant.

-

- Closed the sash.

-

- Turn OFF the Fan & lights.

-

- Turn off the main switch.

-

-

Precaution during handling of Biosafety Cabinet (ESCO) :

-

-

- Do not put any object on the air grill.

-

- Do not use toxic, explosive or flammable substance in Biosafety Cabinet (ESCO).

-

- Avoid UV exposure to eyes and skin.

-

- Do not block front side or back air grill.

-

Qualification of Biosafety Cabinet (ESCO)

-

- Frequency: Once in six months ±15 days.

-

- The qualification of BSC required:

-

-

- If any failure observed during routine monitoring.

-

-

-

- In case of breakdown, maintenance, preventive maintenance.

-

-

-

- In case of change in installation location.

-

-

-

- As per schedule

-

-

-

Procedure of Biosafety Cabinet (ESCO) Qualification:

-

-

- Following tests are performed during qualification and results are within acceptance criteria.

-

-

- Down flow velocity test.

-

-

-

- PAO test.

-

-

-

- Particle count test.

-

-

-

- Smoke pattern test

-

-

-

Procedure of Down flow Velocity Test:

-

-

- Remove the U.V lamp, make a grid of 5 test points on the work zone.

-

- Place the thermo anemometer at a height of 10cm from the lower end of the sash, and take the 5 readings and report in Annexure-2

-

- Acceptance criteria: 0.30±0.02 m/s

-

-

PAO (Poly alpha olefin) Test/ filter integrity test:

-

-

- Ensure that the filter integrity test of the ULPA (Ultra-low particulate air )filter done by using PAO (Poly Alfa Olefin).

-

- Acceptance criteria: The penetration level should be less than 0.01%.

-

- Particle count test:

-

- Ensure that particle count of the work station is done by using a calibrated air borne particulate matter counter.

-

- Acceptance criteria: As per ISO Class 5

≥ 0.5µ particles: NMT 3520 particles per m3

≥ 5.0µ particles : NMT 20 particles per m3

-

-

Smoke pattern test:

-

-

- Using the Smoke Generator generate the smoke behind the sash, in the center of the working zone to demonstrate the laminarity of the air flow in the work zone.

-

- Acceptance criteria:

-

- The smoke must gradually come down being sucked by the front and back grilles.

-

- Generate the smoke just behind the sash to demonstrate that the inner air does leak to the exterior.

-

- Acceptance criteria:

-

- The smoke generated must not leak to the exterior of the cabinet.

-

- Generate the smoke by placing the smoke generator at the level of the armrest, to demonstrate that the air does not enter into the work zone.

-

- Acceptance criteria:

-

- The front grilles must suck in the smoke generated, without entering the work zone.

-

- Qualification shall be done by external agency if facility not available at location.

-

- After Completion of Qualification write the details and pest as per Annexure-3.

7.0 ANNEXURES:

Annexure- 1: Operation Record of Biosafety Cabinet (ESCO)

| Date | Cleaning | UV Light | |||

| Start Time | End Time | Start Time | End Time | Total Burning Hours | |

| Velocity | Operation | Operated by | Checked by | ||

| Inflow (0.45±0.02m/s) | Downflow (0.30±0.02m/s) | Start Time | End Time | ||

Annexure-2 : Qualification Report of Biosafety Cabinet (ESCO)

Instrument Id:

Date of Qualification:

Next Due Date:

- Down flow Velocity Test:

| INSTRSUMENT DETAILS: | |||

| INSTRUMENT : | |||

| MAKE/Model : | |||

| INSTRUMENT I.D : | |||

| Calibration Done: | Next Due Date: | ||

| Reading No. | Anemometer Reading (m/s) | Acceptance criteria |

| 01 | ||

| 02 | ||

| 03 | ||

| 04 | ||

| 05 | ||

| Average Readings |

Result: The average reading obtained is within acceptance criteria.

- PAO (Poly alpha olefin) Test/ filter integrity test:

| Model No. | Sr. No. | Avg. velocity m/s | Filter Integrity (%) | Remarks |

Filter Leak Acceptance: Maximum Particle penetration of 0.01%. No filter leaks present

- Particle count test.

| INSTRSUMENT DETAILS: | |||

| INSTRUMENT : | |||

| MAKE/Model : | |||

| INSTRUMENT I.D : | |||

| Calibration Done: | Next Due Date: | ||

Remarks:______________________________________

| Particle count | |||

| Model | Sr. No. | Particle Size | Observation |

| 0.5µ | |||

| 5.0µ | |||

Smoke pattern test.- The airflow pattern test in the cabinet found to be pass/Fail.

| 1. | ||||

| 2. | ||||

| 3. | ||||

| 4. | ||||

| 5. |

Annexure-3 : Qualification Status Label.

|

MICROBIOLOGY DEPARTMENT |

||

| QUALIFICATION STATUS LABEL | ||

| Name of Instrument | ||

| Instrument ID | ||

| Date of Performance | ||

| Next Due Date | ||

| Performed By | ||