Standard Operating Procedure (SOP) for Handling and Investigation of Extraneous Peak(s) in Chromatography Analysis.

What are the Extraneous Peaks:

A peak response in the chromatogram that is not readily attributable as a characteristic of the injection profiles of the blank, mobile phase, diluting solvent, placebo, standard, or sample solutions.

By definition, extraneous means introduced from an outside source, an adulterant, etc., which is not present in the established chromatographic profile of the injected solution. Per ICH Q3A, Extraneous peak(s) are impurities arising from any source extraneous to the manufacturing process.

HANDLING OF EXTRANEOUS CHROMATOGRAPHIC PEAK

1.0 Purpose :

-

- The purpose of the Standard Operating Procedure (SOP) is to describe the process for handling extraneous peak/s that are not representative of the analyzed materials observed in chromatography.

2.0 Scope :

-

- This SOP applies to extraneous peaks observed during the chromatographic testing of pharmaceutical raw materials, in-process, finished products, and stability samples.

-

- If the extraneous peaks are above the threshold defined in this procedure, an investigation shall be performed to determine the source and the identity of the peak(s)

-

- EXCLUSIONS

-

- This SOP is not applicable to method validation, method verification, method transfer activities, and analysis of non-GMP samples.

3.0 Responsibilities: Handling of Extraneous Peak/s-

-

-

The laboratory Analyst shall be responsible for-

-

-

- Follow procedures as defined in this SOP – Handling of Extraneous Peak(s) during Chromatography.

-

- Inform Laboratory Management or designee about the extraneous peak(s) obtained during the analysis.

-

- Perform the investigation of the extraneous peaks observed.

-

Analytical Data Reviewer shall be responsible for-

-

- Follow procedures as defined in this SOP – Handling of Extraneous Peaks during Chromatography.

-

- Ensure all data is reviewed.

-

- Inform analyst of any deficiencies identified.

Related: SOP for Analytical Data Review.

-

- Ensure good documentation practices are followed and are in compliance with the procedure.

-

- Inform Laboratory Management or designee about the Extraneous Peaks obtained during review.

-

Head Quality Control shall be responsible for-

- Ensure site procedures are being followed.

-

- Assist in the investigation of the extraneous peaks.

-

-

Head Quality Assurance shall be responsible for-

- Performing investigations jointly with the Laboratory.

-

-

- Initiate shop floor investigation in coordination with manufacturing/ Manufacturing Science and Technology Group (MSTG)/ Product Development (PD) departments as needed.

-

- Quality assurance (QA)/designee is responsible for final approval of the investigation and final batch disposition.

4.0 Abbreviations and Definitions -Handling of Extraneous Peak/s :

-

-

Baseline Noise :

-

-

- Baseline noise is the system measurable variation caused by different inherit factors attributable to the nature of the analysis of the system itself (e.g. electric signal fluctuations, detector instability, temperature fluctuations, etc.).

-

Corrective and Preventive Action (CAPA):

- A concept within current Good Manufacturing Practice (cGMP) that focuses on the systematic investigation of root causes of unexpected incidences to prevent their recurrence (corrective action) or to prevent their occurrence (preventive action).

-

- Corrective Action: Action taken to eliminate the causes of an existing nonconformity, defect, or other undesirable situation, in order to prevent a recurrence.

-

- Preventative Action: Action taken to eliminate the cause of a potential nonconformity, defect, or other undesirable situation, in order to prevent occurrence.

-

Extraneous Peak :

- A peak response in the chromatogram that is not readily attributable as a characteristic of the injection profiles of the blank, mobile phase, diluting solvent, placebo, standard, or sample solutions.

-

- By definition, extraneous means introduced from an outside source, an adulterant, etc., which is not present in the established chromatographic profile of the injected solution. Per ICH Q3A, Extraneous peaks are impurities arising from any source extraneous to the manufacturing process

-

-

Identification Threshold :

- A limit above which an impurity shall be identified.

-

-

-

Limit of Detection (LOD) :

- The lowest amount of analyte in a chromatogram can be detected but not necessarily quantitated as an exact value.

-

-

- It is also defined as a peak with a magnitude of three times the measured baseline noise.

-

-

Limit of Quantitation (LOQ) :

- The lowest amount of analyte or unknown impurity peak in the chromatogram can be quantitatively determined with suitable precision and accuracy.

- Also defined as a peak with a magnitude often times the measured baseline noise.

-

Placebo (or Blank) :

-

-

- A dosage form that is identical to the drug product except that the drug substance is absent or replaced by an inert ingredient or a mixture of the drug product excipients quantitatively equivalent to those found in the drug product dosage form.

-

Qualification Threshold :

- A limit above which an impurity shall be qualified.

-

-

Reporting Threshold :

- The reporting threshold is a level above which an impurity must be reported.

-

5.0 Procedure for Investigation of Extraneous Peak :

-

-

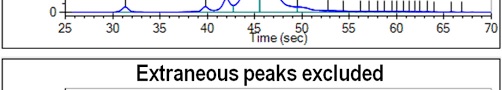

Examination of Chromatograms and Detection of Extraneous Peak(s) :

-

-

- Both the analyst and data reviewer shall examine the analysis chromatograms in expanded scale and compare them to the

-

-

- Blank

-

-

-

- Mobile phase,

-

-

-

- Diluent

-

-

-

- Placebo

-

-

- Standard, and sample chromatograms contained within the analytical test method, corresponding method validation report, and/or method transfer report (if applicable) to identify if an extraneous peaks is present.

-

-

Disregard the following peaks when examining a chromatogram for extraneous peaks and capture details in test record:

-

-

-

- Peaks eluting at the solvent front or void volume, unless the chromatographic profile is significantly atypical.

-

-

-

- The peaks at the solvent front can come from: (1) the counter ion for an active drug substance that is salt, (2) formulation excipients for a drug product, or (3) solvent disturbances produced by injection.

-

-

-

- Peaks due to solvent /diluent used to prepare samples.

-

-

-

- Extraneous peak(s) noted in standard but not in samples.

-

-

-

- Extraneous peaks noted in the resolution solution or prepared by forced degradation,

-

-

-

- Used to confirm system suitability parameters as per the requirement of the test procedure.

-

-

-

- Placebo/excipient peaks identified in the test method or method validation report or placebo chromatograms obtained at the time of analysis.

-

-

-

- The extraneous peak in limit tests exclusive to specific component or element or ions

-

-

-

- Peaks in High-Performance Liquid Chromatography (HPLC) sample chromatograms obtained using gradient elution chromatography.

-

-

-

- That is observed at the same retention time in the chromatogram obtained for injection.

-

-

-

- Identification of peak in the chromatogram as active, specified impurities/degradation products, or preservatives.

-

-

-

- Peaks eluted in gradient elution due to gradient changes and solvent effects of the chromatographic run.

-

-

-

-

Degradation peaks noted during forced degradation studies at the time of method validation.

- Any peak observed during stability study that was previously investigated in any previous time points.

-

-

-

-

- Any peak in residual solvent analysis observed after the diluent or solvent peak (Dimethylformamide, Dimethylsulfoxide, etc.) typically called high boilers.

-

-

-

- The peak observed in one injection which is not observed in other duplicate injections is considered as an artifact and not an extraneous peak.

-

-

-

- In the case of drug release/ dissolution profile studies if an extraneous peak is not noted in all the chromatograms generated from the same vessel sample solution, then the source of the extraneous peak can be determined to be laboratory error.

-

-

-

- Record such details in the test record.

-

-

- The observation and evaluation of any extraneous peak must be documented in the testing record.

-

-

Determination of Concentration of Extraneous Peak(s):

- All extraneous peaks not disregarded (as per the above section) shall be measured for its magnitude.

-

-

- The magnitude of an extraneous peak may be calculated using the formula per the analytical test method and evaluated as below:

-

-

- Where the analytical test method does not contain a calculation formula for determination of the magnitude of the peak, (including methods not involving external standard quantification) the % Area/Area calculation may be used.

-

-

-

- Extraneous peak concentration (%) =

-

(Response of extraneous peak x100)

(sum of responses of all peaks in chromatographic run excluding blank/ solvent/ placebo peaks).

-

-

- For Assay/ Blend uniformity/ Content uniformity/ Dissolution/ preservative tests, estimate the extraneous peak against standard response:

-

-

-

- Extraneous peak concentration (%) =

-

(Response of extraneous peak x100)

(response of standard peak)

-

-

- For combination products involving multiple components, estimate the magnitude of any extraneous peak in Assay, Dissolution, Content Uniformity, or Blend Uniformity chromatograms against the sum of the peak responses of all components in Standard chromatogram.

-

-

-

- Extraneous peaks concentration (%) =

-

(Response of extraneous peak x100)

(sum of responses of standard components)

-

-

- For extraneous peaks obtained in Residual Solvent analysis by Gas Chromatography determine the concentration of extraneous peaks against the response of standard exhibiting the lowest response.

-

-

-

- Extraneous peak (ppm) =

-

(Response of extraneous peak x theoretical ppm of residual solvent exhibiting lowest standard response)

(response of standard exhibiting lowest response in the chromatographic run).

-

-

The Threshold to Qualify Extreneous Peak(s) for Investigation:

- Any peak(s) that is not disregarded shall be estimated for its magnitude/ concentration.

-

-

- Any extraneous peak determined to be more than the threshold given below shall be subjected to investigation by following the procedure given in the next section.

-

-

- In the case of Assay, Dissolution, Drug Release, Content Uniformity, Blend Uniformity, Preservative content if the extraneous peak is more than 5%.

-

-

-

- Dissolution and Drug Release if the extraneous peak is more than 2%.

-

-

-

- In the case of Residual Solvents by GC if the extraneous peak is more than 10 ppm.

-

-

-

Investigation and Determination of Source of Extraneous Peaks :

- The source of an extraneous peak could be one of the following, but not limited to…

-

-

-

- Product-related; e.g. contamination during the manufacturing or sampling process.

-

-

-

- A process-related impurity introduced when a vendor changed their manufacturing process without providing the notification of the changes or the existence of the process-related impurity.

-

-

-

- Laboratory error related; e.g. glassware contamination, gloves, improper instrument maintenance, handling of analyzed materials, sample filter, etc.

-

-

-

If the extraneous peak(s) concentration in-

-

-

-

- Assay,

- Assay,

-

-

-

- Content Uniformity,

-

-

-

- Blend Uniformity,

-

-

-

- Dissolution/Drug Release,

-

-

-

- Preservative content,

-

-

-

- Residual Solvents is more than the threshold criteria

-

-

-

- It shall be investigated as per site-specific.

-

-

-

For extraneous peaks observed in Dissolution/Drug Release test chromatograms, examine the following as part of the preliminary investigation.

-

-

-

- Examine the Assay and Content Uniformity testing chromatograms if test methods are similar to determine the source of the extraneous peak(s).

-

-

-

- Examine different time interval chromatograms obtained from the same dissolution vessel sample solution to determine.

-

-

-

- If the source of the extraneous peak is due to syringe/ vessel/ cannula/auto-sampler, etc.

-

-

- Where test methods are the same for different quality attributes examine the chromatograms and compare against chromatograms generated using a similar method to determine the source of extraneous peaks.

-

- When possible, analyze one sample solution containing extraneous peak(s) on an HPLC equipped with PDA to compare the UV spectra to the primary sample peak.

-

- In the case of a drug substance or excipient extraneous peak, contact the vendor for assistance to investigate the root cause.

-

-

The preliminary investigation (re-analysis) of an extraneous peak may include, but is not limited to the following steps where applicable-

-

-

-

- Inject the same vial to identify any injection/ instrument related artifacts.

-

-

-

- Fill a new vial with the same solution and make a single injection to identify any sample vial / syringe-related artifacts.

-

-

-

- Re-filter the sample solution and make a single injection to identify any filter/ syringe related artifacts.

-

-

-

- The re-dilute stock solution where applicable and make a single injection to identify any glassware/pipette/solution handling artifacts.

-

-

-

- A placebo preparation may be injected as an investigational tool to determine the source of the extraneous peak.

-

-

-

- Extend the run time to explore if the extraneous peaks are related to carry over peaks.

-

-

-

- Evaluate the injections made during the preliminary investigation.

-

-

-

- If an assignable cause is found, e.g.

-

-

-

-

- Attributable to the filter,

-

-

-

-

-

- Glassware,

-

-

-

-

-

- Pipette,

-

-

-

-

-

- Carryover peak or instrument/chemist error,

-

-

-

-

-

- Establish appropriate CAPA if applicable to address the root cause as per the respective procedure.

-

-

-

- If an assignable root cause is not determined during the preliminary investigation (re-analysis),

-

- Prepare individual excipient/ component solutions with higher concentrations using the same lot of materials (when possible) in batch/ lot under investigation to determine the source of the extraneous peak.

-

-

If an assignable root cause is not determined during the preliminary investigation, perform re-testing by, at minimum, following the steps below:

-

-

-

- Prepare fresh sample solution for re-test in single user, if available, an aliquot of the same sample (same sample of tablet/powder/liquid ).

-

-

-

- The assignable root cause is not determined during re-test, prepare sample solution using freshly sampled solid sample or different liquid

-

-

-

- Evaluate injections made during re-testing.

-

-

-

- If the assignable cause is identified, e.g. attributable to sample preparation, sampling error, contamination, etc. establish appropriate CAPA as per site-specific procedure to address the root cause.

-

-

- If the extraneous peak is attributable to laboratory error,

-

- No further investigation steps are required.

-

- Appropriate CAPA shall be established if deemed necessary.

-

- In the case of extraneous peak(s) in Residual Solvent analysis,

-

- The peak may be due to the solvent used in component manufacturing or from the penultimate stage of manufacturing.

-

- In such cases, a review of drug substance, excipient residual solvent statement may help to determine if the extraneous peak is due to one of the residual solvent.

-

- If a clear assignable cause is not identified, either after or concurrent with re-analysis/ re-test studies, the Laboratory Management or designee shall conduct a comprehensive review of the method validation packages, and any other related sources to identify potential sources of the extraneous peaks.

-

-

This shall include a review of the following (but not limited to)…

-

-

-

- Past history, such as laboratory investigations and chromatograms for testing of stability samples for previous stability time points.

-

-

-

- Evaluation of sample chromatograms from the testing of different lots/batches of the drug substance/ drug product to determine if the peak has previously been observed.

-

-

-

- The current investigation shall be linked to previous investigations to provide continuity and documented as part of the investigation.

-

-

-

- Special attention must be given to chromatograms of placebo (stressed and unstressed) or any other data.

-

-

- If the assignable root cause is not determined during re-test investigation carried out with a laboratory sample, extend the investigation to the shop floor by coordinating with PD/ MSTG/Production.

-

- As part of the shop floor investigation, review batch records, previously manufactured products, material sampling processes, cleaning records, and other possible sources of contamination.

-

-

- The investigation shall extend to other batches of the same drug product or other drug products (as necessary) that may have been associated with the specific discrepancy.

-

-

-

- If the assignable root cause is attributed to manufacturing/ sampling/ cleaning/contamination, establish appropriate CAPA to address the root cause as per the specific procedure.

-

Note: Re-sampling shall be performed using appropriate approved procedures.

-

Batch Disposition :

- If the investigational outcome is attributed to laboratory error,

-

- It is justifiable to report the results from the original analysis (disregarding the extraneous peak) for batch disposition decisions.

-

-

- If the extraneous peak is not observed in the injection of there- vialed/ re-filtered solution,

-

-

-

- But the peak was still observed in reinjection of the original vial, then the instrument/ vial artifact is confirmed.

-

-

-

- If the extraneous peak is not observed in the injection of the re- diluted solution,

-

-

-

- But the extraneous peak remained to be observed in the re-injection of the re-filled vial/ re-filtered vial, then sample preparation artifact due to glassware contamination is confirmed.

-

-

-

- If the extraneous peak under investigation corresponds to any of the individual excipients/ components used in the lot/ batch under investigation, then the source of the extraneous peak is confirmed to be input material.

-

-

-

- If the extraneous peak is not observed in the re-test chromatogram obtained from a freshly prepared laboratory sample, then the original sample preparation artifact is confirmed.

-

-

-

- In the case of Drug Release/Dissolution profile studies, if the extraneous peak is not noted in all the chromatograms generated from the same vessel sample solution, then the source of the extraneous peak can be determined to be laboratory error.

-

-

- If the extraneous peak is determined to be affecting the accuracy of results due to incomplete resolution of the extraneous peak from the component of interest, re-test results shall be considered as reportable results.

-

- The lot/batch under investigation shall be rejected if shop floor investigation attributes the source of the extraneous peaks as a product/ manufacturing issue.

-

Identification of Extraneous Peaks :

- If the extraneous peak is concluded as product-related impurity then identification of the molecular structure and source of the extraneous peak must be performed.

-

- A combination of chromatographic and spectroscopic tools may be needed as part of the investigation. like…

-

-

- Gas Chromatography-Mass Spectrometry,

-

-

-

- Liquid Chromatography with Photodiode Array Detection,

-

-

-

- Liquid Chromatography-Mass Spectrometry,

-

-

-

- X-Ray Diffraction, etc.

-

6.0 References :

-

- Guidance for Industry, “Q2 (R1) Validation of Analytical Procedures Text and Methodology” ICH Nov 2005.

-

- Guidance for Industry, “Q3A (R2) Impurities in New Drug Substances”, ICH 25 October 2006.

-

- European Medical Agency-Guideline on the Limit of Genotoxic Impurities, June 2006

-

- Guidance for Industry, “Q3B (R2) Impurities in New Drug Products”, ICH 2 June 2006.

-

- Guidance for Industry, “Q3C (R5) Impurities: Guideline for Residual Solvents”, ICH 4 February 2011.