Standard Operating Procedure (SOP) for Work Permit System in Pharmaceutical drug manufacturing plant. The work permit system is a formal written procedure used to control the hazards in non-routine work.

The different work permit highlights the relevant hazards and precaution to be taken for the respective work before starting the activity.

Procedure for Work Permit System

1.0 PURPOSE:

-

- To lay down a procedure to safeguard plant, person, and equipment while carrying out dangerous operations like

-

-

- Cold Work,

-

-

-

- Hot Work,

-

-

-

- Work on Height,

-

-

-

- Work on Fragile,

-

-

-

- Vessels & Confined Space entry,

-

-

-

- Excavation,

-

-

-

- Electrical,

-

-

-

- Lock Out Tag Out (LOTO) and

-

-

-

- Lift Maintenance through the contractor, service provider, or by company staff.

-

2.0 SCOPE – SOP FOR WORK PERMIT SYSTEM:

-

- This procedure is applicable to different types of work described in this procedure, where there are a hazard and a non-routine work to be carried out when dangerous operations are to be carried out inside the factory premises which at the pharmaceutical drug manufacturing plant.

3.0 REFERENCES:

-

- In House

-

- EHS Guideline (Permit To Work System)

-

- EHS Guideline (Lock Out Tag Out – LOTO)

-

- SOP: Procedure for Contractor Safety Management.

4.0 RESPONSIBILITY – SOP FOR WORK PERMIT SYSTEM:

-

-

Initiator Department shall be responsible for :

-

-

- The department personnel shall initiate the safety work permit approval as per the SOP format.

-

- Start the work only after taking the work permit form consent.

-

- The job initiator shall check & review the permit checkpoints at the job site only at the time of issuing the work permit.

-

-

Job Initiator / Area In-charge / Electrical In-charge shall be responsible for:

-

-

- Proper planning, issue, and return of permit shall be properly coordinated, a clear idea about the job task & related hazard.

-

- Handle the team with safe work procedures ensuring company safety rules & regulations.

-

- Electrical In-charge ensures the proper electrical connection for Hot Work & LOTO Permit to avoid electrocution & fire incident.

-

-

Contractor Supervisor shall be responsible for:

-

-

- To handle his team ensuring company Safety rules & regulations and a clear understanding of the job task.

-

- Proper equipment with safety guards shall be used at the worksite.

-

-

User Department Head / EHS Department Head or Designee:

-

-

- To ensure that work can not be stated without an approved work permit and the safe work procedure is followed at the work/job site.

5.0 ABBREVIATIONS:

-

- ELCB: Earth Leakage Circuit Breaker

-

- LEL: Lower Explosive Level

-

- LOTO: Lock Out Tag Out

-

- NRV: Non-Return Valve

-

- PPE’S: Personal Protective Equipment’s

6.0 DEFINITION:

-

-

Work Permit System:

-

-

- The work permit system is a formal written procedure used to control the hazards in non-routine work.

-

- The different permit highlights the relevant hazards and precaution to be taken for the respective work before starting the activity.

-

-

Non Routine Work:

-

-

- The work which is performed except the daily routine work is considered as non-routine work.

-

- In other words Activity/work which is installed through the work order system and do not have SOP’s is considered as non-routine work. E.g. installation or modification of equipment, painting, repair, or maintenance/service of machines.

-

-

Hot Work:

-

-

- Hot Work is any work, where chances of generation of heat (E.g. Works involving spark/burning, welding, cutting, grinding, soldering, etc.)

-

-

Height Work:

-

-

- Height Work is defined as working at any place that is 6 ft. (1.8 meters) above the ground or 6 ft. (1.8 meters) from any edge without any primary protection. Ladder, fixed work platform, or metal scaffolding with solid guardrails is should be used while performing to avoid the fall hazard (i.e. fall from height).

-

- It depends on the risk of fall hazard safety net also to be fixed as secondary protection.

-

- All equipment like a ladder, Scaffolding, fall arresters should be check while performing the job.

-

-

Cold Work:

-

-

- Any nonroutine work is done by an employee, contractor, vendor, or service provider which has hazards involved, e.g. loading/unloading of heavy equipment/material, installation of equipment, electrification of equipment, laying of cables, painting, non-routine maintenance, etc.

-

-

Fragile Roof:

-

-

- The roofs are not designed to bear the load and thus are unable to support a person’s weight.

-

- Persons standing on fragile and brittle roof surfaces are at risk if the roof breaks and gives away under their weight.

-

- Those roofs are constructed from molded or fabricated materials such as glass, fiberglass, acrylic, etc.

-

-

Confined Space:

-

-

- A confined space is, that has limited or restricted means for entry or exit and is not designed for continuous occupancy.

-

- A confined space that does not contain or, with respect to atmospheric hazards, have the potential to contain any hazard capable of causing the death or serious physical harm. (E.g. of Confined Space are boiler, process vessels, drains, sewage drains, AHU ducts, chimney, Flue stack, etc.)

-

- Confined Space entry required for any vessels, equipment, or substation which is not suitable for continuous occupancy and has only limited entry /exit point.

-

- There must be at least 3 persons at the site all the time when the work is performed.

-

-

Excavation Work:

-

-

- It is a work that involves digging in earth/ground or concrete and has the chances of damaging underground electric cables, pipelines, or other services.

-

- This can be done manually or with the help of machines.

-

- Excavation Permit has to be applied for more than 1-meter excavations.

-

-

Electrical Work:

-

-

- Any work which requires handling electrical energy and has the potential to cause injury to the person. For e.g. any new installations or trouble shootings.

-

-

Workplace:

-

-

- An establishment, a job site, or project at one geographical location containing one or more work areas.

-

-

Hazard:

-

-

- Any source or any situation at the workplace with the potential to cause bodily injury or ill-health.

-

- Hazard can be physical, chemical, environmental, ergonomics, and biological.

-

-

Hazardous Energy:

-

-

- Energy sources like electrical, mechanical, pneumatic, chemical, thermal, or any other sources which, if not controlled can cause harm to people and damage property and environment.

-

-

Energy Isolating Device:

-

-

- A mechanical device that physically prevents the transmission or release of energy, including but not limited to the following:

-

-

- A manually operated electrical circuit breaker,

-

-

-

- Disconnect switch,

-

-

-

- A manually operated switch by which conductors of a circuit can be disconnected from all ungrounded supply conductors and, in addition,

-

-

-

- No pole can be operated independently;

-

-

-

- A line valve;

-

-

-

- A block; and

-

-

-

- Any similar device used to block or isolate energy.

-

-

-

- Remarks – On/Off switches,

-

-

-

- Push buttons,

-

-

-

- Selector switches,

-

-

- e-stops and other control circuit type devices are NOT energy isolating devices.

-

-

Lockout Tag Out:

-

-

- The placement of a lockout and tag out the device on an energy isolation device to ensure that equipment cannot start and there is no potential for energy release.

-

- The main purpose is to prevent the unexpected start-up of equipment or release of energy and also to prevent injury, equipment damage, and property loss.

-

-

Affected Employee:

-

-

- An employee whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is being performed under lockout or tag out or, whose job requires him/her to work in an area in which such servicing or maintenance is being performed.

-

-

Authorized Employee:

-

-

- A person who locks out or tags out machines or equipment in order to perform servicing or maintenance on that machine or equipment.

-

- An affected employee becomes an authorized employee when that employee’s duties include performing servicing or maintenance that exposes him/her to potentially hazardous energy.

-

- Authorized employees will be issued locks with numbers and tag – “Do Not Operate”.

-

- These are not used for any other purpose. Remarks – No other locks or tags shall be used for LOTO.

-

-

Stored Energy:

-

-

- Residual Hazardous energy that exists even after the machine/equipment is an isolate.

-

- This energy can be found in flywheels, capacitors, pressurized gases, and fluids.

7.0 PROCEDURE FOR WORK PERMIT SYSTEM:

-

-

General Overview about Work Permit System :

-

-

- The work permit is a document which used to control certain types of work like cold work, hot work, height & fragile roof work, vessel & confined space entry, excavation work, electrical work, lockout tag out (LOTO) and lift maintenance work which is identified as potentially hazardous.

-

- Work Permits are the key document associated with the permit system.

-

- The permit should be considered whenever it is intended to carry out any work which may adversely affect the safety of personal, the environment or the plant.

-

- They are normally considered to be more appropriate for non-routine jobs.

-

- The work permit system shall be used to ensure safe working by eliminating possible associated high risks.

-

- In different permit, relevant hazards shall be identified and precaution shall be taken for the respective work before starting the activity.

-

- In other words, the work permit system used when work is performed by employees and or third parties which may be a non-routine work / hazardous routine works not covered by procedures.

-

- The work permit shall be used while performing the non-routine activities inside the factory premises and different permit shall be intended to carry out any work which may adversely affect the safety of personal, the environment or the plant.

-

-

Issuance of Work Permit :

-

-

- Permit number shall be assigned as – EHS/WP No. XXXX.

-

-

- Where,

-

-

-

- EHS – Environment, Health & Safety

-

-

-

- WP No. – Work Permit Number

-

-

-

- XXXX – Representing sequential numbers like 0001, 0002, etc.

-

-

- Each permit contains 3 copies, where first copy shall remain with contractor at work site only; second copy with EHS department & third copy is the book copy.

-

- Work Permit will be valid for only one day. Next day if same work at same location needs to be done then it should be extended in extension column by re-checking the permit conditions at job site only.

-

- Permit shall be canceled due to violation of safety rules leading to a life-threatening situation and or Work condition changed due to emergency.

-

- In case of emergency declaration, immediately work will be stop and evacuated from the worksite and assembled at the emergency assembly point.

-

- After getting an all-clear sign. working shall be resumed.

-

-

Requisition for Issuance of Work Permit :

-

-

- The permit shall be initiated by the job initiator, engineering department, area in-charge, contractor supervisor and EHS in-charge.

-

- Jab initiator shall be filled in the required details at job site only or after verification of the job site, Also area in-charge, contractor supervisor/representative, electrical in-charge EHS In-charge will sign.in the permit and ensure the checkpoints are maintained at the worksite.

-

- All the precautions / Checkpoints shall be thoroughly checked & fill in the permit checklist.

-

- Mark [√] for operation / work carry out, mark [x] for operation/work should not carry out. NA for Not applicable

-

- Toolbox talks shall be conducted & maintain the training record, explain the person / contractor about the job, tools and personal protective equipment (PPE’s) to be used.

-

- The signature shall be done by the person & contractor representative/supervisor in this permit log.

-

-

Safety instruction shall be strictly followed which is written in a work permit.

-

-

- Persons who are going to carry out the work will use the right tools and PPE’s as given in the work permit.

-

- Contractors or service providers shall follow the site safety rules and regulations, if any kind of unsafe work observed during the job, disciplinary action to be taken as per SOP for Procedure for contractor Safety Management.

-

- For Vessel and confined space entry the permit shall be verified engineering and or production in-charge before approval of EHS.

-

- Each working site shall be supervised by the supervisor and a work permit should be available to the work site only with the person performing the job & at the time of verification he should retain the valid permit.

-

- During the course of work, permit signatories shall be randomly checking the safety measures taken or not taken at the worksite.

-

-

Safety Instructions during the execution of permitted work :

-

-

- Safety officer / in-charge / design. shall confirm all the details filled in the work permit and release the permit to carry out the work/job.

-

- In the absence of EHS in-charge / EHS officer or design. Engineering in-charge will be authorized to approve the work permit and sign. on behalf of EHS.

-

- Safety officer / in-charge / design. shall be check randomly during the job and report any serious deficiencies to the concerned Head of the departments and plant head.

-

- In case a measure gap in permit compliance, he should stop the work, ensure to correct the unsafe conditions, and then start the work.

-

- If the same work at the same location needs to be done after the earlier stipulated time, then it shall be extended in the extension column by re-checking the permit condition at the job site.

-

- If any unexpected hazardous situation arises or job conditions change during the course of work, stop the work immediately.

-

- Information shall be given to the permit signatories regarding the unexpected hazardous situation.

-

-

Remove the hazard and minimize the risk, then start and complete the work.

-

-

- Depends upon the risk factors of Hot Work and Vessels and confined space entry, safety In-charge / safety officer/design. shall be checking the LEL level.

-

- For Vessel & confined space entry oxygen level should be between 19.5 to 23.5 %. Depending on the job and work conditions % of Oxygen (O2) check should be done at a certain frequency until the work is completed.

-

- In the case of lift maintenance, permit taken and all checkpoints should be thoroughly verified.

-

- Lockout and Tag Out (LOTO) shall be prepared to prevent a workplace incident due to hazardous energy and unexpected release of stored energy.

-

- The hazardous energy in an equipment/machine should be identified, removed, or controlled before any accidental exposure to the hazards.

-

- The machine/equipment Lock Out Tag Out (LOTO) is to be performed shall be shut down as per the user department’s normal SOP.

-

- Before starting any kind of maintenance / any new installations/trouble shootings for the risk of hazardous energy, LOTO should be strictly followed.

-

- Anyone who operates or uses equipment or machine in which servicing or maintenance is being performed under lockout tag out refers to the affected employee.

-

- Anyone who locks out and tags out equipment in order to perform servicing, maintenance, or internal cleaning refers to the authorized employees.

-

- The affected employee shall be informed to the engineering team for use LOTO, whereas the authorized employee will confirm the completion of the activity and ensures the equipment/machine safe to operate i.e. – guards are placed on rotating parts, all tools and tackles are removed and housekeeping is done

-

-

Outside Contractors shall follow lock out tag out policy and procedures.

-

-

- Following steps to be followed in the application of lock out tag out (LOTO) –

-

- Notify affected employees to shut down the machine using normal shut down procedures for the equipment to be locked out.

-

- De-activate to be done by the energy isolation device(s) (such as switches, valves, circuit breakers, etc.) to isolate the machine from all energy sources. (Disconnect Locations)

-

- Lockout and tag out the isolating device with the Locks and Name I.D. “Do Not Operate” tag to be applied.

-

- To ensure/dissipate or restrain stored or residual energy in springs, air-lines, capacitors, etc..

-

- To verify that equipment is isolated from all energy sources by trying to turn it on. After verification, place the start / stop back in a neutral position.

-

- The machine will be now locked out and tagged out.

-

-

These things are again verified by the authorized employee, he will verify and confirm the following checkpoints.

-

-

-

- Check the machine and the immediate area to ensure all non-essential items have been removed and that equipment components are operationally intact. (Guards in place, machine parts in place, tools not left in equipment, etc.)

-

-

-

- Ensure that all employees have been safely positioned or removed from the area.

-

-

-

- Verify that the start/stop controls are neutral.

-

-

-

- Remove the lockout tag-out devices and re-energize the equipment.

-

-

-

- Inform the affected employees that the servicing and maintenance is completed and is ready to use.

-

-

- If a group of individuals is to work, then each of them has to apply the Lock Out Tag Out (LOTO) device and the following steps.

-

-

- One person in the group will be responsible for coordinating the lockout tag out the procedure before work begins to ensure each person understands the task.

-

-

-

- Each employee in the group must review the lockout tag out the procedure to be used.

-

-

-

- A group of individuals shall be used on the disconnect for each employee to affix his / her lock and tag.

-

-

-

- Each authorized employee shall affix his / her lock and tag before beginning work and must remove them upon completion of their work.

-

-

-

- In case of shift or personnel change Employees shall discuss the status of maintenance or servicing and any other notification of start-up or testing to be performed.

-

-

- Once the job is completed, housekeeping shall be done and any loose materials like welding slugs, cut-outs, etc. should be disposed of in the right manner. Job initiating person/user should ensure this and proceed for the permit closure.

-

- After completion of permit closure, a work permit shall be submitted to the EHS department for records.

-

-

Types of Work Permit :

-

-

- Types of Permits used inside our plant premises are given below –

-

-

- Cold Work Permit

-

-

-

- Hot Work Permit

-

-

-

- Height & fragile roof Work Permit

-

-

-

- Vessel & Confined Space Entry Work Permit

-

-

-

- Excavation Work Permit

-

-

-

- Electrical Work Permit

-

-

-

- Lock Out Tag Out (LOTO) Permit

-

-

-

- Lift Maintenance Work Permit

-

- Workflow chart for different permits as shown below –

Cold Work Permit

Approval Steps –

Job Initiator ⇒ Contractor ⇒ Area Incharge ⇒ EHS

Hot Work Permit

Approval Steps –

Job Initiator ⇒ Electrical Incharge ⇒ Contractor ⇒ Area Incharge ⇒ EHS

Height & fragile roof Work Permit

Approval Steps –

Job Initiator ⇒ Contractor ⇒ Area Incharge ⇒ EHS

Vessel & Confined Space Entry Work Permit

Approval Steps –

Job Initiator ⇒ Contractor ⇒ Area Incharge ⇒ Production / Engineering Incharge ⇒ EHS

Excavation Work Permit

Approval Steps –

Job Initiator ⇒ Contractor ⇒ Area Incharge ⇒ Utility In-charge ⇒ EHS

Electrical Work Permit

Approval Steps –

Job Initiator ⇒ Electrical Incharge ⇒ Contractor ⇒ Area Incharge ⇒ EHS

Lock Out Tag Out (LOTO) Permit

Approval Steps –

Job Initiator ⇒ Shift In-charge ⇒ Maintenance Incharge ⇒ Engg. In-charge ⇒ EHS

Life Maintenance Work Permit

Approval Steps –

Job Initiator ⇒ Electrical In-charge ⇒ Contractor / Service Engg. ⇒ Area In-charge ⇒ EHS

-

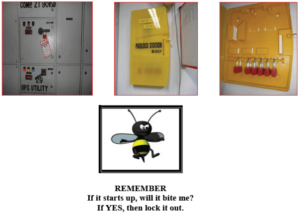

- Some safety signage for dangers relating to different workplace hazard is shown below.

For LOTO Device

-

- On/Off switches, pushbuttons, selector switches, e-stops, and other control circuit type devices are NOT energy isolating devices.

8.0 DISTRIBUTION – SOP FOR WORK PERMIT:

-

- Quality Control

-

- Production

-

- Warehouse

-

- Engineering

-

- Quality Assurance

-

- EHS

-

- Personnel and Administration

9.0 ANNEXURES – SOP FOR WORK PERMIT:

Annexure 1: Cold Work Permit

EHS / WP No. – _______________________

|

(Please Tick where applicable)

JOB INITIATOR/PERFORMEREquipment: ______________________ Location of Work: _______________ Date _________ Valid From _______ Hrs. To ______ Hrs. Name of Contract Agency:______ Name of Job Supervisor:__________________________________________ No. of Person worked / to be work: ________________________________ Description of Work ______________________________________________ Any other Permits Applied:_________________________________________ (Please mention the relevant permit no. also) |

HAZARD EVALUATION❑ Pinch Point ❑ Flammable/combustible ❑ Noise ❑ Elevated Work ❑ lifting ❑ Nitrogen or other Gas ❑ Slip. Trip and Fall ❑ Hot Surface ❑ Dust ❑ Sharp edges ❑ Electrical ❑ Toxic Chemical ❑ Rotating parts ❑ Any Other |

| THE FOLLOWING ITEMS SHALL BE CHECKED BEFORE ISSUING THE PERMIT

PERSONAL PROTECTIVE EQUIPMENT (PPE) ❑ Helmet ❑ Safety Shoes / Gumboot ❑ PVC Suit ❑ Gloves ❑ Mask ❑ Goggles ❑ Ear Plugs / Muff ❑ Face Shield ❑ Full-body Harness/Belt❑ Respirator ❑ Welding Hood ❑ BA Set |

CHECKPOINTS:

Special Instruction (If any): ______________________________________________ |

| We agree that the above-mentioned safety measures have been taken and the relevant permit for work may be issued.

Job Initiator Contractor Area In-charge EHS Name:__________ Sign: ___________ |

EXTENSION TO VALIDITY OF SAFETY PERMITWe agree that the work location is re checked and above mentioned safety measures have been maintained so relevant permit work may be extended from _____________hrs to ______________hrs on Dt – ____________________ Job Initiator Contractor Area In-charge EHS Name:__________ Sign: ___________ |

| Permit Closure: Job completed Satisfactory, all the electrical connections done and area housekeeping is done.

Job Initiator Name:__________ Date: __________ Sign: __________ Time: ___________ |

Permit Cancelled:

Name: _________Date: ________ 1) Due to violation of safety rules leading to life-threatening situation. ❑ 2) Work conditions changed due to emergency ❑ |

SPECIAL INSTRUCTIONS1. In case of emergency alarm, all work must be stopped. All personnel must leave the worksite and proceed to the designated assembly points. 2. Due to emergency if work conditions have changed, the earlier permits should be canceled and new permits to be applied. 3. In the case of liquid/gas release, stop work, and immediately inform the concerned operation personnel. 4. A proper Power tool with ELCB, NRV, etc. as per Safety requirements will only be allowed in the company premises 5. Ensure proper grounding/earthing/insulation of cables. 6. This permit must be available at the worksite at all times. 7. This permit is valid for only one day. The next day if the same work at the same location needs to be done then it can be extended in the extension column by rechecking the permit conditions at the job site only. 8. Each working site must be supervised by an authorized supervisor. 9. Perform housekeeping and the area cleaned after the job complition. 10. Closed Permits should be submitted to the EHS Department for records 11. If any elevated hot work is carried, care should be taken to prevent injuries or incidents due to sparks or molten metals. The area below the hot work should be barricaded. 12. While continuing the work, any abnormality if observed/noticed, shall be immediately reported. Always ensure safe working conditions and PPE compliance. 13. While performing the job must follow the procedure for Contractor Safety Management. 14. The permit shall be prepared in triplicate.

|

Annexure 2: Hot Work Permit

Note: Use the above Format (Format for Cold Work Permit) as such for Hot Work Permit with the following checkpoints…

CHECKPOINTS:

| 1) | Equipment / Work area inspected. | ❑ | 12) | Precautionary signboards provided | ❑ |

| 2) | Considered hazards from other routine Operations and concerned persons alerted. | ❑ | 13) | Stand by personnel provided from Operations / Engineering./Contractor | ❑ |

| 3) | Availability of proper ventilation and lighting. | ❑ | 14) | Area barricaded | ❑ |

| 4) | Proper means of exit/emergency route provided. | ❑ | 15) | Applicable PPE’s, Tools and Equipment provided in good condition | ❑ |

| 5) | Equipment electrically isolated/tagged, fuse removed and LOTO applied. | ❑ | 16) | The contractor/vendor involved in the job is briefed on the job scope and hazard. | ❑ |

| 6) | Surround area checked / clean up; oil / rags / grasses etc. removed. Flammable materials removed | ❑ | 17) | Cutting and welding equipment have ELCB. | ❑ |

| 7) | Equipment check – drained/depressurized flushed & purged | ❑ | 18) | Fire extinguisher/extinguishing media provided to the job site. | ❑ |

| 8) | Equipment inspected, drained / disconnected / closed / isolated / wedges open | ❑ | 19) | Openings / crakes / holes are identified where sparks may are identified and necessary precautions taken. | ❑ |

| 9) | Equipment blinded / disconnected / closed / isolated / wedge open. | ❑ | 20) | Fire watch (standby person) posted at job site. Fire hydrant system in use to any fire emergency. | ❑ |

| 10) | Gas test done. ___________ % LEL. | ❑ | 21) | The surrounding area to be wet down. | ❑ |

| 11) | Spark arrester / Fire blanket/shield provided against the spark generation. | ❑ | 22 | Contractors / Vendors involved in the job are briefed on the job scope and hazards. | ❑ |

Name of the Standby person : |

|||||

Special Instruction (If any): ______________________________________

Annexure 3: Height & fragile roof Work Permit

Note: Use the above Format (Format for Cold Work Permit) as such for Height & Fragile roof Work Permit with the following checkpoints…

CHECKPOINTS:

| 1) | Equipment / Work area inspected. | ❑ | 8) | Precautionary signboards provided | ❑ |

| 2) | Considered hazards from other routine Operations and concerned persons alerted. | ❑ | 9) | Stand by personnel provided from Operations / Engineering./Contractor | ❑ |

| 3) | Proper ventilation and lighting are available / provided. | ❑ | 10) | Area barricaded | ❑ |

| 4) | Proper means of exit/emergency route provided. | ❑ | 11) | Applicable PPE’s, Tools and Equipment provided in good condition | ❑ |

| 5) | Equipment electrically isolated/tagged, fuse removed and LOTO applied. | ❑ | 12) | The contractor/vendor involved in the job is briefed on the job scope and hazard. | ❑ |

| 6) | Ladder / platform / scaffolding provided in good condition. | ❑ | 13) | Safety belt and lifeline provided in good condition. Other precautions like a safety net if necessary provided. | ❑ |

| 7) | Wind direction and other weather conditions are satisfactory. | ❑ | 14) | The area below and around of the Height worksite is barricaded | ❑ |

Special Instruction (If any): _______________________________________________

Annexure 4: Vessel & Confined Space Entry Work Permit

Note: Use the above Format (Format for Cold Work Permit) as such for Vessel & Confined Space Entry Work Permit with the following checkpoints…

CHECKPOINTS:

| 1) | Equipment / Work area inspected. | ❑ | 12) | Precautionary signboards provided. | ❑ |

| 2) | Considered hazards from other routine Operations and concerned persons alerted. | ❑ | 13) | Stand by personnel provided from Operations / Engineering/Contractor. | ❑ |

| 3) | Proper ventilation and lighting are available / provided. | ❑ | 14) | Area barricaded (if required) | ❑ |

| 4) | Proper means of exit/emergency route provided. | ❑ | 15) | 24 V Lamp supplied with ELCB. (If required) | ❑ |

| 5) | Equipment electrically isolated/tagged, fuse removed and LOTO applied. | ❑ | 16) | Applicable PPE’s, right equipment/tools used. | ❑ |

| 6) | Surround area checked/cleaned up; Oil / rags / grass etc. Removed flammable materials removed. | ❑ | 17) | The boiler steam valve closed or blanked. | ❑ |

| 7) | Equipment drained/depressurized/flushed & purged and cooled to ambient temperature. | ❑ | 18) | Boiler feedwater closed or blanked. | ❑ |

| 8) | Equipment blinded / disconnected / closed / isolated from the process. | ❑ | 19) | The boiler blowdown valve closed/blanked. | ❑ |

| 9) | Safe accesses/ladders provided and found in good working condition. | ❑ | 20) | Boiler cooled down | ❑ |

| 10) | Gas test done. _________ % LEL and ________ % O 2 | ❑ | 21) | Utility or other hazardous chemical lines isolated / blanked. | ❑ |

| 11) | Safety belt & lifeline provided & found in good working condition. | ❑ | 22) | The contractor/vendor involved in the job is briefed on the job scope and hazard. | ❑ |

| 23) | The rescue plan is prepared. | ❑ |

Special Instruction (If any): ______________________________________

Annexure 5: Excavation Work Permit

Note: Use the above Format (Format for Cold Work Permit) as such for Excavation Work Permit with the following checkpoints…

CHECKPOINTS:

| 1) | Equipment / Work area inspected. | ❑ | 8) | Precautionary signboards provided. | ❑ |

| 2) | Considered hazards from other routine Operations and concerned persons alerted. | ❑ | 9) | Stand by personnel provided from Operations / Engineering/Contractor. | ❑ |

| 3) | Ensure the availability of proper ventilation and lighting. | ❑ | 10) | Area barricaded. | ❑ |

| 4) | Proper means of exit/emergency route provided. | ❑ | 11) | Applicable PPE’s, right equipment/tools used. | ❑ |

| 5) | Material and equipment of support system selected based on soil characters & trench depth. | ❑ | 12) | Briefing to Contractors/vendors involved in the job for the job scope and hazards. | ❑ |

| 6) | Review the area/site layout plan. | ❑ | 13) | Hard barricading done around the excavated area. | ❑ |

| 7) | Underground electric cables, service/utility lines, and other pipelines identified and disconnected. | ❑ | 14) | Emergency rescue equipment available & plan available. | ❑ |

Special Instruction (If any): ______________________________________________

Annexure 6: Electrical Work Permit

Note: Use the above Format (Format for Cold Work Permit) as such for Electrical Work Permit with the following checkpoints…

CHECKPOINTS:

| 1) | Equipment / Work area inspected. | ❑ | 6) | Precautionary signboards provided. | ❑ |

| 2) | Considered hazards from other routine Operations and concerned persons alerted. | ❑ | 7) | Stand by personnel provided from Operations / Engineering/Contractor. | ❑ |

| 3) | Area barricaded. | ❑ | 8) | Applicable PPE’s, right equipment/tools used. | ❑ |

| 4) | Proper means of exit/emergency route provided. | ❑ | 9) | Provide proper earthing to the equipment | ❑ |

| 5) | Equipment electrically isolated/tagged, fuse removed / capacitors discharged and LOTO applies. | ❑ | 10) | Briefing of contractors/vendors involved in the job for the job scope and hazards. | ❑ |

| Name & sign. of the standby Person – | Name & Sign. of the electrical in-charge | ||||

Special Instruction (If any): ________________________________________________

Annexure 7: Lock Out Tag Out (LOTO) Permit

| Initiated By: | Date: | Time: |

| Department: | Equipment Name: | |

| Equipment ID: | Location of the Equipment: | |

| Type of Hazardous energy: (Electrical, Mechanical, Pressure, Chemical, steam): | ||||

| PPE’s: ❑ Helmet ❑ Safety Shoes ❑ Gloves ❑ Goggles ❑ Ear Plugs / Muff ❑ Full body Harness / Belt | ||||

FILLED BY SHIFT IN-CHARGE |

||||

| LOTO PROCEDURE | LOCKOUT & TAG OUT(LOTO)

ACTION

|

CHECK POINTS: Put Tick mark where applicable. (√) | Yes | N.A. |

| 1) Information sharing to concerned persons? | ||||

| 2)Removal of Fuse | ||||

| 3) Depressurization of filters | ||||

| 4) Stop the Utility supply like steam, air, water stopped? | ||||

| 5) Disconnection status of battery terminal? | ||||

| 6) Does the supply line valve put ‘OFF’? | ||||

| 7) Is the machine/equipment clean to perform task? | ||||

| 8) Is Machine shut down as per the normal procedure | ||||

| 9) Mention if any specific control. | ||||

| Electrical/Pneumatic/ Steam connection disconnected and Tag/Lock out put on by:

(Specify the lock No.__________ ) |

||||

| Sign: Date:Time: | ||||

| Checked by (Name of Maintenance In-charge): | ||||

| VERIFICATION | Additional safety precautions (if any): | ||

| Engineering in-charge signature | EHS in-charge signature | ||

| REMOVE OF LOTO | CHECKPOINTS: The following points to be checked before switching on by Engg. dept.: | Yes | N.A. | |||

| Loose connection | ||||||

| All earthling wire connected | ||||||

| All safety devices in place: | ||||||

| Air/steam leaking | ||||||

| Electrical/Pneumatic/ Steam supply switched and Tag/Lockout removed by: | ||||||

| Name of Electrician/Technician: | Sign. & Date: | Time: | ||||

| Verification by user shift in charge: | Sign. & Date: | Time: | ||||

| Verification by EHS dept. | Sign. & Date: | Time: | ||||

Annexure 8: Lift Maintenance Permit

Note: Use the above Format (Format for Cold Work Permit) as such for Lift Maintenance Permit with the following checkpoints…

CHECKPOINTS:

Special Instruction (If any): ________________________ |

||||||||||||||||||||||||||||||||||||||||||||||||

For More EHS related SOP’s: Please Click – EHS SOP’s

Pingback: Personal Protective Equipment (PPE) usage - Pharma Beginners

Pingback: Grounding Requirement for Equipment and Building - Pharma Beginners

Pingback: Cross Contamination, Mix-Ups & Microbial Contamination - SOP in Pharma